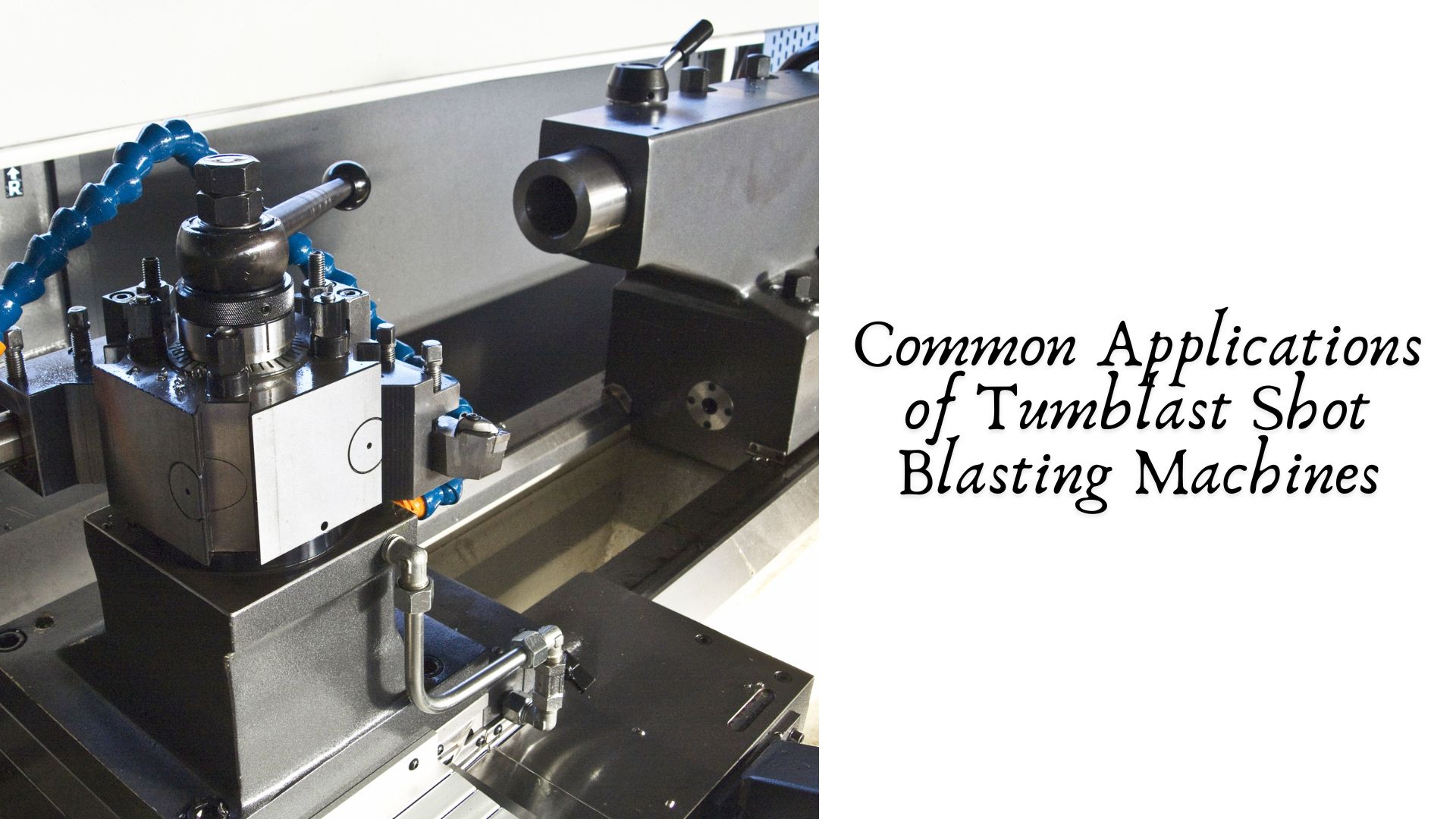

Tumblast shot blasting machines are integral tools in modern manufacturing and surface treatment industries. Their versatility, efficiency, and effectiveness make them invaluable for a wide range of applications. This article explores the common uses of tumblast shot blasting machines, highlighting their importance in various industrial processes.

Introduction to Tumblast Shot Blasting Machines

Tumblast shot blasting machines are a type of abrasive blasting equipment designed to clean, strengthen, and polish metal parts. These machines operate by propelling abrasive materials, such as steel shots or grits, against the surface of the workpiece. The tumbling action ensures that all surfaces of the workpieces are uniformly exposed to the blasting medium. This process removes contaminants, enhances surface texture, and prepares the materials for further processing.

Surface Cleaning and Preparation

One of the primary applications of tumblast shot blasting machines is surface cleaning. These machines effectively remove rust, scale, paint, and other contaminants from metal surfaces. This is crucial in industries such as automotive, aerospace, and construction, where clean and contaminant-free surfaces are necessary for ensuring the quality and durability of the final products.

Rust and Scale Removal

Rust and scale build-up on metal parts can lead to corrosion and weaken the structural integrity of the components. Tumblast shot blasting machines excel at removing these unwanted layers, restoring the metal to its original state. This process is especially important for parts that will be exposed to harsh environmental conditions or undergo further processing, such as welding or coating.

Paint and Coating Removal

In industries where parts are frequently painted or coated, tumblast shot blasting machines are used to strip old paint or coatings. This is essential for refurbishing old equipment or preparing surfaces for new coatings. The machines ensure a clean and roughened surface, which improves the adhesion of new paint or coating, thereby extending the lifespan and improving the appearance of the parts.

Surface Texturing and Finishing

Tumblast shot blasting machines are also employed for surface texturing and finishing. This involves creating a specific surface profile on metal parts to improve their functional and aesthetic qualities. The process can be tailored to achieve various textures, from a smooth, polished finish to a rough, textured surface.

Surface Roughening

Surface roughening is often required for parts that need to have better adhesion properties for subsequent coatings or bonding processes. Tumblast shot blasting machines create a uniform rough surface, which enhances the mechanical bond between the metal and the applied coatings or adhesives. This application is common in the aerospace and automotive industries, where components must meet stringent bonding and coating standards.

Polishing and Smoothing

Conversely, tumblast shot blasting machines can also be used for polishing and smoothing metal parts. By carefully selecting the abrasive media and controlling the blasting parameters, manufacturers can achieve a smooth, polished finish on their components. This is particularly important in industries like medical device manufacturing, where smooth surfaces are crucial for ensuring hygiene and reducing friction.

Deburring and Deflashing

Deburring and deflashing are essential processes in the manufacturing of precision metal parts. Tumblast shot blasting machines are highly effective at removing burrs and flash from castings, forgings, and machined parts. These unwanted materials can affect the performance, fit, and safety of the components.

Deburring

Deburring involves the removal of sharp edges and protrusions (burrs) that are left on metal parts after machining or cutting. Tumblast shot blasting machines can quickly and efficiently remove these burrs, resulting in smoother and safer components. This application is critical in industries such as electronics, where burrs can interfere with assembly processes, and in the medical field, where sharp edges can pose safety risks.

Deflashing

Deflashing refers to the removal of excess material (flash) that escapes from the mold during the casting or forging process. Tumblast shot blasting machines effectively remove this excess material, ensuring that the parts meet precise dimensional tolerances and have a clean, professional appearance. This is particularly important in the automotive and aerospace industries, where high precision and reliability are paramount.

Peening for Material Strengthening

Shot peening is a process used to improve the mechanical properties of metal parts. It involves bombarding the surface of the material with small, spherical media, which induces compressive stresses on the surface. Tumblast shot blasting machines are widely used for shot peening applications to enhance the fatigue strength, stress corrosion resistance, and overall durability of metal components.

Fatigue Strength Enhancement

Fatigue strength is a critical factor in the performance of metal parts subjected to cyclic loading. Shot peening with tumblast shot blasting machines increases the fatigue strength of these parts by introducing compressive stresses, which counteract the tensile stresses that cause fatigue failure. This application is common in the aerospace and automotive industries, where components such as gears, springs, and structural parts are subjected to repeated loading.

Stress Corrosion Resistance

Stress corrosion cracking is a major concern in many industries, particularly those involving harsh environmental conditions. Shot peening with tumblast shot blasting machines helps to mitigate this issue by inducing compressive stresses that inhibit the initiation and propagation of cracks. This is crucial for ensuring the long-term reliability and safety of components used in critical applications.

Mold Cleaning and Maintenance

In the plastic and rubber molding industries, maintaining clean and properly functioning molds is essential for producing high-quality parts. Tumblast shot blasting machines are used to clean molds by removing residues, such as rubber, plastic, and release agents, that accumulate during the molding process. This helps to extend the lifespan of the molds and ensures consistent product quality.

Rubber and Plastic Residue Removal

Residues left behind from rubber and plastic molding processes can negatively impact the performance and longevity of the molds. Tumblast shot blasting machines efficiently remove these residues, restoring the molds to their original condition and preventing defects in future production cycles. This application is vital for maintaining the efficiency and productivity of molding operations.

Maintenance of Precision Molds

Precision molds, used in industries like electronics and medical device manufacturing, require regular maintenance to ensure their accuracy and functionality. Tumblast shot blasting machines play a key role in this maintenance by providing thorough and precise cleaning without damaging the delicate mold surfaces. This ensures that the molds produce high-quality parts with consistent dimensions and finishes.

Conclusion

Tumblast shot blasting machines are indispensable tools in a wide range of industrial applications. From surface cleaning and preparation to peening for material strengthening, these machines offer versatile and efficient solutions for improving the quality and durability of metal parts. Their ability to remove contaminants, enhance surface texture, and perform precise cleaning and finishing tasks makes them essential for industries demanding high standards of quality and performance. As technology continues to advance, tumblast shot blasting machines will undoubtedly remain a cornerstone of modern manufacturing and surface treatment processes.

Name: Eye of The Tiger

Address: Kolkata, West Bengal, India

P.No.: 70039 76182