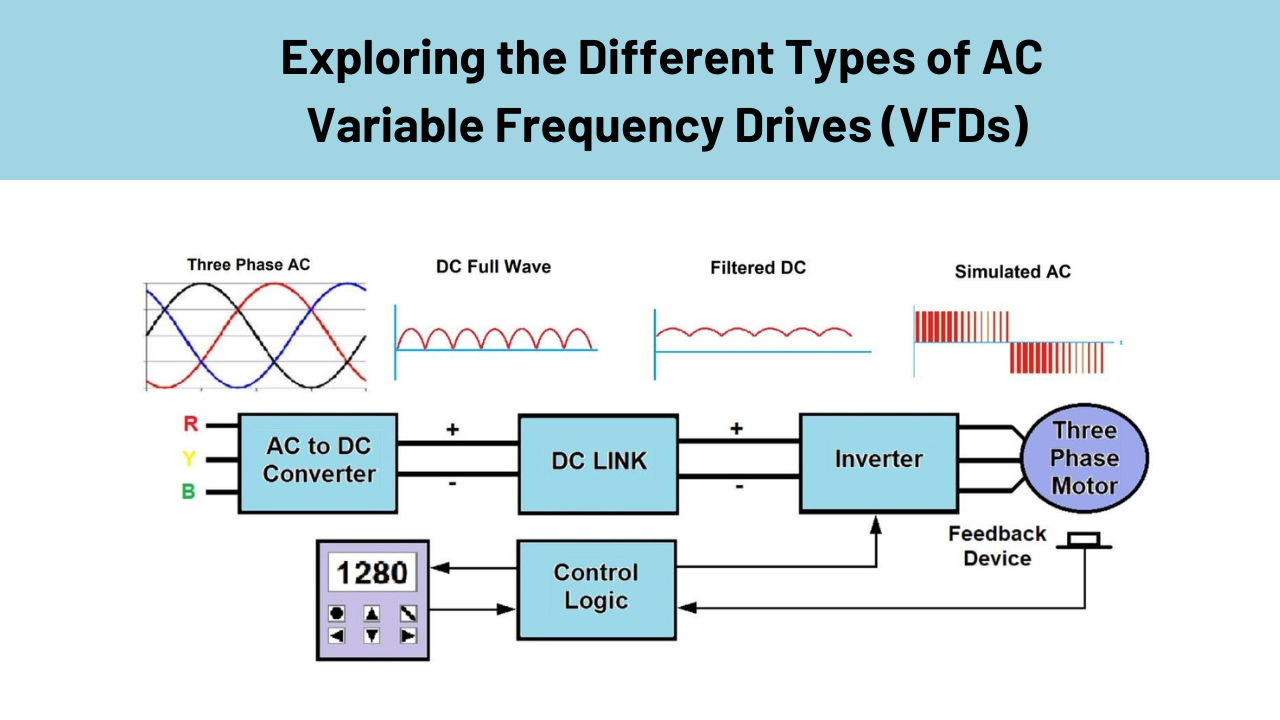

Variable frequency drives (VFDs) are essential components in industrial automation and motor control systems because they provide accurate, flexible, and efficient speed regulation for AC motors. Across industries, VFDs are used in a variety of applications, such as energy saving programs and HVAC systems in manufacturing.

1. Voltage Source Inverter (VSI) Drives:

Supply of Voltage The most prevalent kind of AC VFDs are inverter drives. They function by employing a rectifier to transform the AC input voltage into DC voltage, which is then converted back to AC at different frequencies and voltages to regulate the motor speed using an inverter. The simplicity, dependability, and controllability of VSI drives are well recognized.

2. Current Source Inverter (CSI) Drives:

Current Source Inverter drives control the output current rather than the output voltage, in contrast to VSI drives. In some applications, they offer superior stability and short-circuit safety and are powered by a current-regulated DC power source. However, because of their intricate control needs, they are less prevalent than VSI drives.

3. PWM (Pulse Width Modulation) Drives:

PWM drives are a common motor control technology that are a kind of VSI drives. To regulate the effective voltage and frequency sent to the motor, they alter the pulse width in the output waveform. PWM drives are energy-efficient and provide exact control over motor speed and torque.

4. Scalar (V/f) Control Drives:

Motor speed is controlled using scalar control drives that concurrently modify voltage and frequency. To guarantee steady flux in the motor, they keep the voltage to frequency (V/f) ratio constant. Although scalar control is easy to use and reasonably priced, it might not offer as fine control as vector control techniques.

Check :- Rockwell Automation PowerFlex 4M AC Drive

5. Vector Control (Field-Oriented Control) Drives:

Through separate torque and magnetic flux regulation, vector control drives provide extensive control over the motor. Comparing them to scalar control, they offer better speed management, greater torque at low speeds, and better dynamic reaction. When great performance and precision are required, vector control is the best option.

6. Direct Torque Control (DTC) Drives:

One type of vector control drive that does not require coordinate transformations is the DTC drive, which directly controls motor torque and flux. Fast and accurate torque control is what they provide, making them appropriate for robotics and machine tool applications where quick torque response is essential.

7. Sensorless Vector Control Drives:

Drives using sensorless vector control estimate motor parameters using voltage and current feedback, doing away with the necessity for speed or position feedback sensors. These drives are less expensive and easier to install, although they could perform a little bit worse than drives with sensors.

8. Closed-Loop Control Drives:

Closed-loop control drives precisely alter motor speed based on data from position or speed sensors. They continually compare the intended speed to the actual motor speed and modify the output as necessary. Closed-loop control is necessary for applications needing great precision as it guarantees exact speed regulation.

9. Open-Loop Control Drives:

Open-loop control drives function without receiving input from position or speed sensors. They don’t track motor performance in real time, but they do offer rudimentary speed control. Open-loop drives are less complicated and costly, but they might not be appropriate for applications that need exact speed control.

10. Multi-Level Inverter Drives:

Multi-Level Inverter drives reduce harmonic distortion and increase efficiency by producing several voltage levels using multiple power semiconductors. They are appropriate for applications sensitive to harmonics and provide a smoother output voltage waveform than conventional two-level inverters.

There are several varieties of AC Variable Frequency Drives, each with benefits and applications that they are suitable for. Application-specific requirements, cost, efficiency, and necessary performance all play a role in selecting the appropriate kind. There is an AC VFD drive type to suit practically every need in commercial and industrial environments, whether it is basic speed control or high-performance torque regulation. Engineers may enhance motor control systems for performance and efficiency by making well-informed judgments based on their understanding of these kinds.

When you require variable frequency drives for your manufacturing industry system, Asteam Techno Solutions Pvt Ltd is here to help you. With an inventory of obsolete and surplus spare parts and a team of qualified engineers, there’s no breakdown or fault we cannot solve. Wherever you are in the world, Asteam Techno Solutions Pvt Ltd is the best Industrial Automation parts supplier and solutions provider in India as well as globally. Get support for all types of equipment from AC, DC and servo drives through to PLCs, HMIs and other automation parts. Hard to find parts are a specialty, with fast shipping on obsolete parts from all brands including Allen Bradley, Mitsubishi, Omron, Siemens, Schneider, Moxa, VIPA and more.