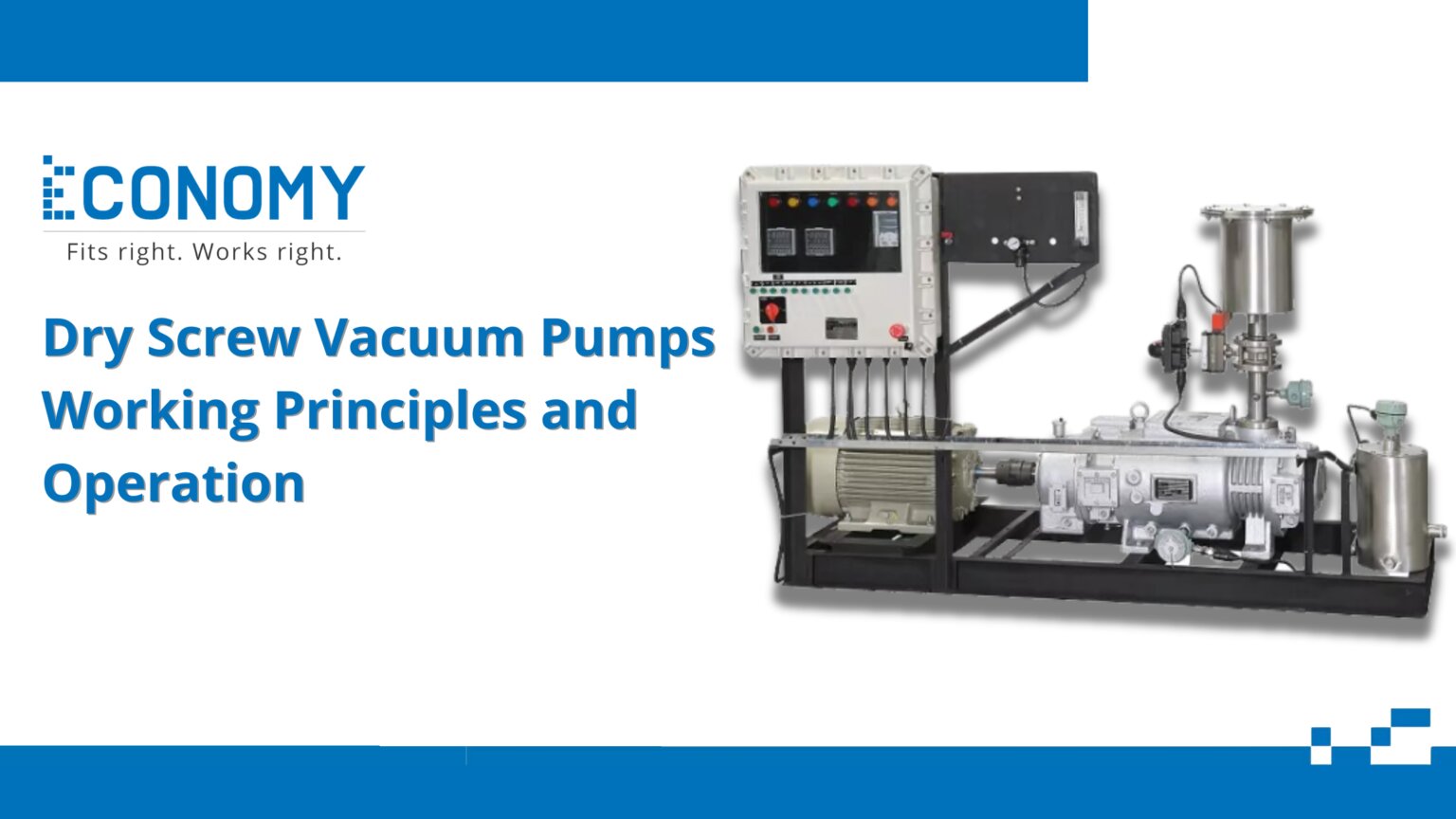

Dry screw vacuum pumps play a crucial role in various industries by providing an efficient, oil-free means of creating a vacuum. These pumps are designed to handle a range of gases without the risk of contamination, making them essential for processes requiring high levels of cleanliness and reliability.

Introduction to Dry Screw Vacuum Pumps

Dry screw vacuum pumps are a type of positive displacement pump, characterized by their dry, lubricant-free operation. They are used to create vacuums by moving gas through the pump using intermeshing screw rotors. This design is particularly beneficial in industries where even minimal contamination from lubricants or oils is unacceptable, such as in pharmaceuticals, food processing, and semiconductor manufacturing.

Basic Principles and Operation of Dry Screw Vacuum Pumps

The basic principles and operation of dry screw vacuum pumps of positive displacement. The pump features two screw-shaped rotors that rotate in opposite directions. As these rotors turn, they trap gas between the threads of the screws and the pump casing. This trapped gas is then moved along the length of the screws from the intake to the exhaust side. The decreasing volume between the screws compresses the gas, increasing its pressure before it is expelled through the exhaust port. This continuous process effectively creates a vacuum in the desired system.

One of the key aspects of dry screw vacuum pumps is the precise engineering that ensures the rotors do not touch each other or the casing. This non-contact operation is vital for maintaining a lubricant-free environment and reducing wear, thereby extending the pump’s operational life and efficiency.

Components of Dry Screw Vacuum Pumps

The main components of dry screw vacuum pumps include the rotors, timing gears, pump casing, inlet and exhaust ports, and seals and bearings. The rotors are the core elements, designed to intermesh without contact, thus driving the gas through the pump. Timing gears ensure the synchronization of the rotors, crucial for preventing mechanical failure and maintaining efficiency. The pump casing houses the rotors and forms the chamber for gas compression. Inlet and exhaust ports facilitate the entry and exit of gas, while seals and bearings support the rotors, ensuring smooth, frictionless operation and maintaining vacuum integrity.

Advantages and Disadvantages of Dry Screw Vacuum Pumps

Dry screw vacuum pumps offer several advantages, including oil-free operation, which eliminates the risk of contamination. This makes them ideal for sensitive applications where cleanliness is paramount. They are highly efficient due to their precise design and non-contact operation, which reduces energy losses. Additionally, their design results in low maintenance requirements and a long service life, as there is minimal wear and tear.

However, these pumps also have some disadvantages. They tend to be more expensive initially due to the advanced materials and engineering required. Their complexity can make them more challenging to repair and service, necessitating specialized knowledge and tools. Furthermore, they can generate more noise and vibration compared to other types of vacuum pumps, which may require additional measures to mitigate in certain environments.

Applications in Various Industries

Dry screw vacuum pumps are utilized across a broad spectrum of industries. In chemical processing, they handle corrosive and hazardous gases without the risk of contamination. The pharmaceutical industry relies on these pumps to maintain sterile conditions essential for producing drugs and other medical products. Semiconductor manufacturing requires ultra-clean environments that dry screw vacuum pumps can provide. In food packaging, these pumps ensure vacuum conditions without contaminating food products. They are also used in environmental engineering applications like soil remediation and vapor recovery, helping manage and mitigate pollutants.

Future Developments and Innovations

The future of dry screw vacuum pumps is marked by ongoing innovations aimed at enhancing their performance and expanding their applicability. Advances in materials are enabling the development of pumps that can withstand higher temperatures and more corrosive environments, thus extending their operational life. Improvements in rotor design and motor technology are driving efforts to increase energy efficiency. Additionally, noise reduction technologies are being developed to make these pumps quieter and more suitable for noise-sensitive environments. The integration of sensors and IoT technology for real-time monitoring and predictive maintenance is also on the horizon, promising to enhance reliability and reduce downtime.

Key Takeaways

Dry screw vacuum pumps are essential for industries requiring oil-free, clean vacuum environments. Their operation is based on the positive displacement principle, utilizing synchronized screw rotors to compress and move gas. These pumps offer significant advantages in terms of efficiency, maintenance, and versatility but come with higher initial costs and complexity. Their applications span from chemical processing and pharmaceuticals to semiconductor manufacturing and food packaging. Future developments in materials, energy efficiency, noise reduction, and IoT integration promise to further improve their performance and reliability, making them an even more invaluable tool in industrial applications.